Products

Tungsten Solid Carbide tsvimbo

Carbide Rods Tsanangudzo

Tungsten carbide rods inoshandiswa zvakanyanya kugadzira premium solid solid carbide zvishandiso, senge mill, drills, reamers, milling cutters, stamping, uye maturusi ekuyeresa mumaindasitiri akasiyana.Kedel Tool inogadzira yepamusoro uye inopindirana mhando carbide rods mumagiredhi akasiyana zvinosanganisira K20F, K25F, nezvimwewo. Iyo yakazara yakajairwa kusarudzwa kwe tungsten carbide tsvimbo mumhando dzakasiyana inowanikwa, uye isu tinopawo masevhisi ekugadzirisa zvinoenderana nezvaunoda. Semugadziri weISO, Kedeltool inoshandisa zvinhu zvepamusoro-soro kuvimbisa kunaka uye kushanda kwetsvimbo dzedu dzecarbide. Nekuomesesa kwemhando yekuongorora, tinogona kuve nechokwadi chakaenderana mhando mukati mebatch yega yega.

Kedel Carbide Rod Types

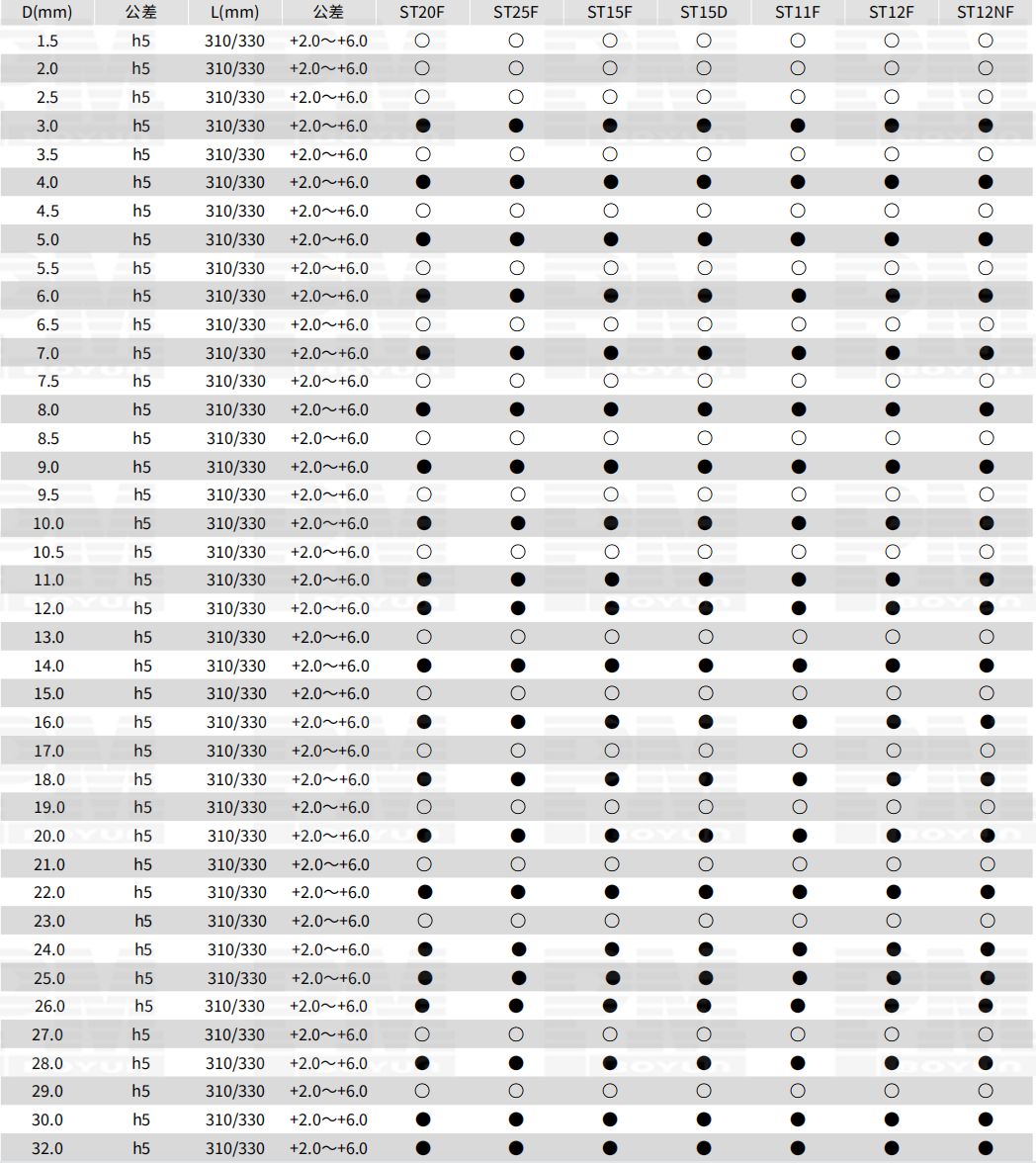

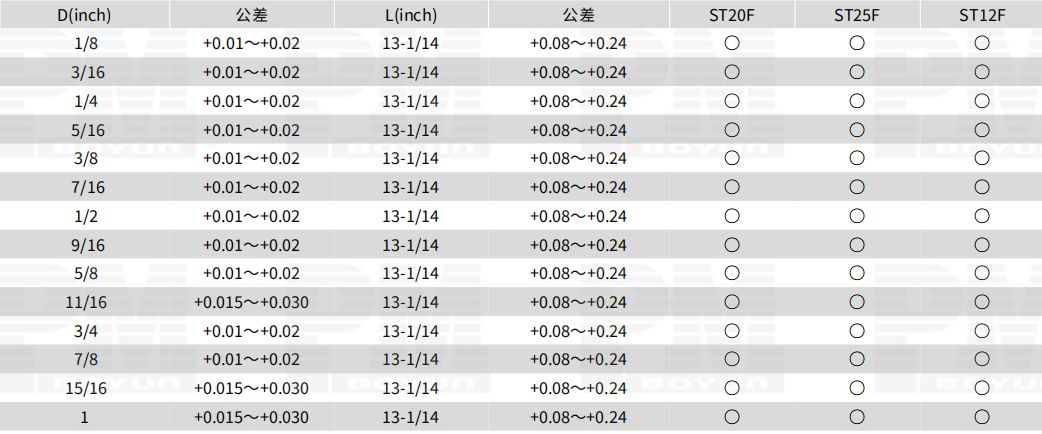

1. Solid Carbide Rods muMetrics

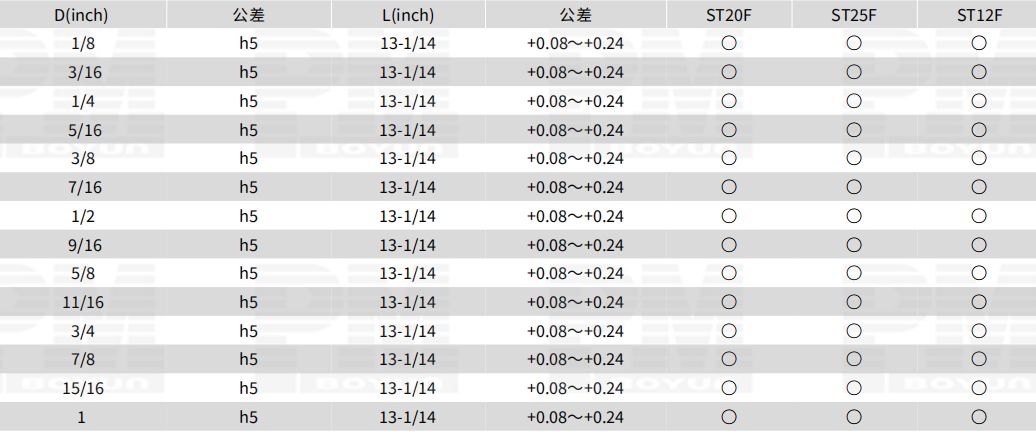

2. Solid Carbide Tsvimbo mumasendimita

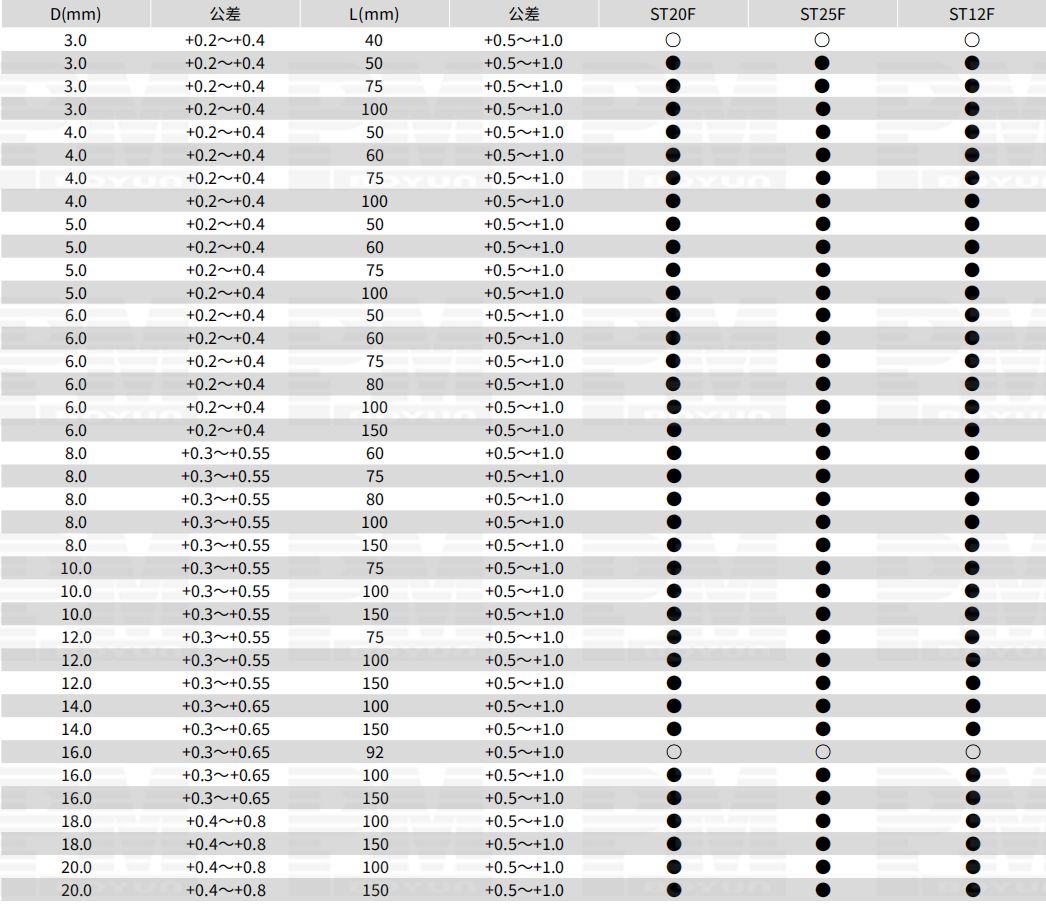

3. Drill Blanks (Chamfered)

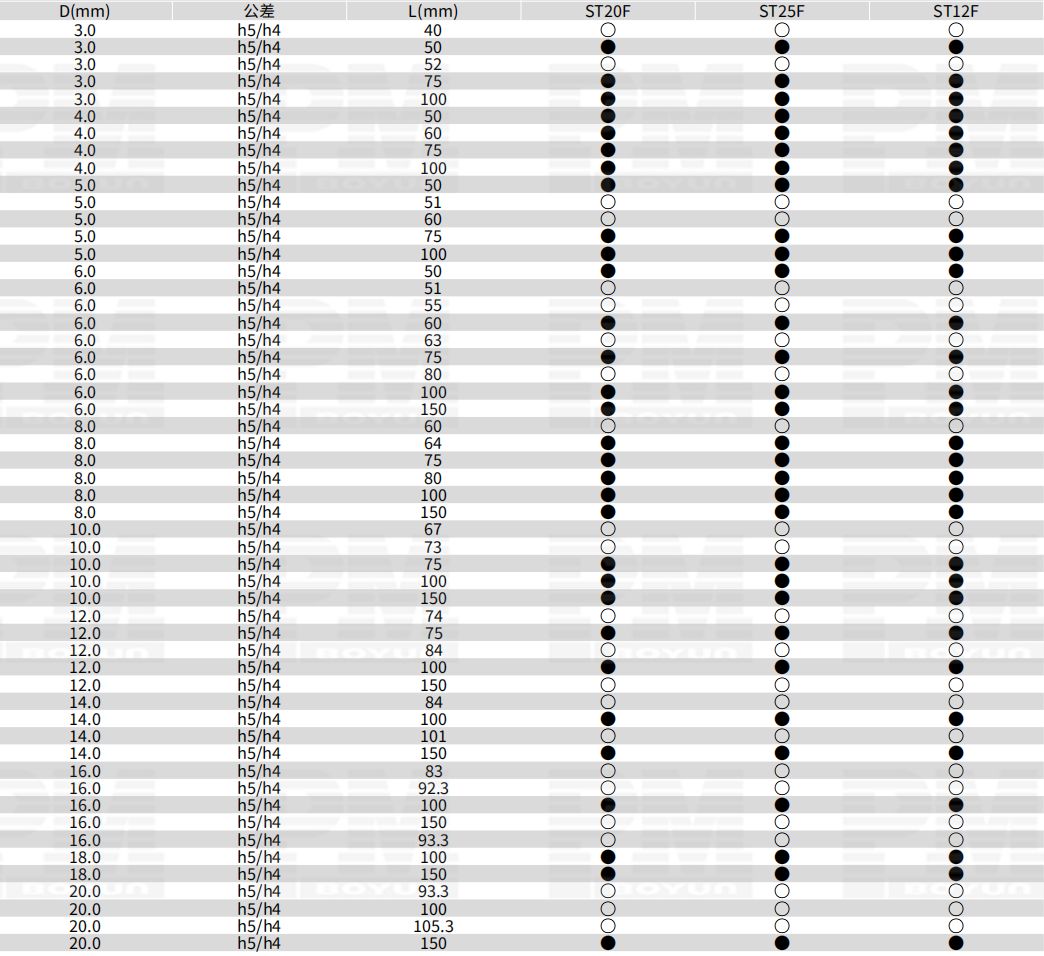

4. End Mill Blanks (Chamfered)

5. Carbide Rods ine A Straight Central Inotonhorera Hole

6. Matanda eCarbide ane Makomba Maviri Akatwasuka Anotonhorera

Carbide Rod Hunhu

1. Yakagadzirwa nemhando yepamusoro tungsten carbide superfine poda

2. Precision midziyo ine 10MPa HIP-Sinter stove yakagadziriswa yakagadzirwa.

3. Kuoma kwepamusoro uye simba rakakwirira

4. Yakakosha mabhenefiti: Kuomarara kwakatsvuka, kupfeka kusagadzikana, yakakwira elasticity modulus, TRS, kugadzikana kwemakemikari, kusagadzika kwemhedzisiro, kuderera kweiyo dilatation coefficient, kupisa conduction uye electric conduction zvakafanana nesimbi.

5. Yakakosha tekinoroji: yakanyanya kudzvanywa sintering yekupisa tembiricha vacuum. Deredza porosity, kuderedza compactness uye michina midziyo. Various giredhi, mhando uye saizi.

6. Giredhi rakasiyana rereferensi yako.

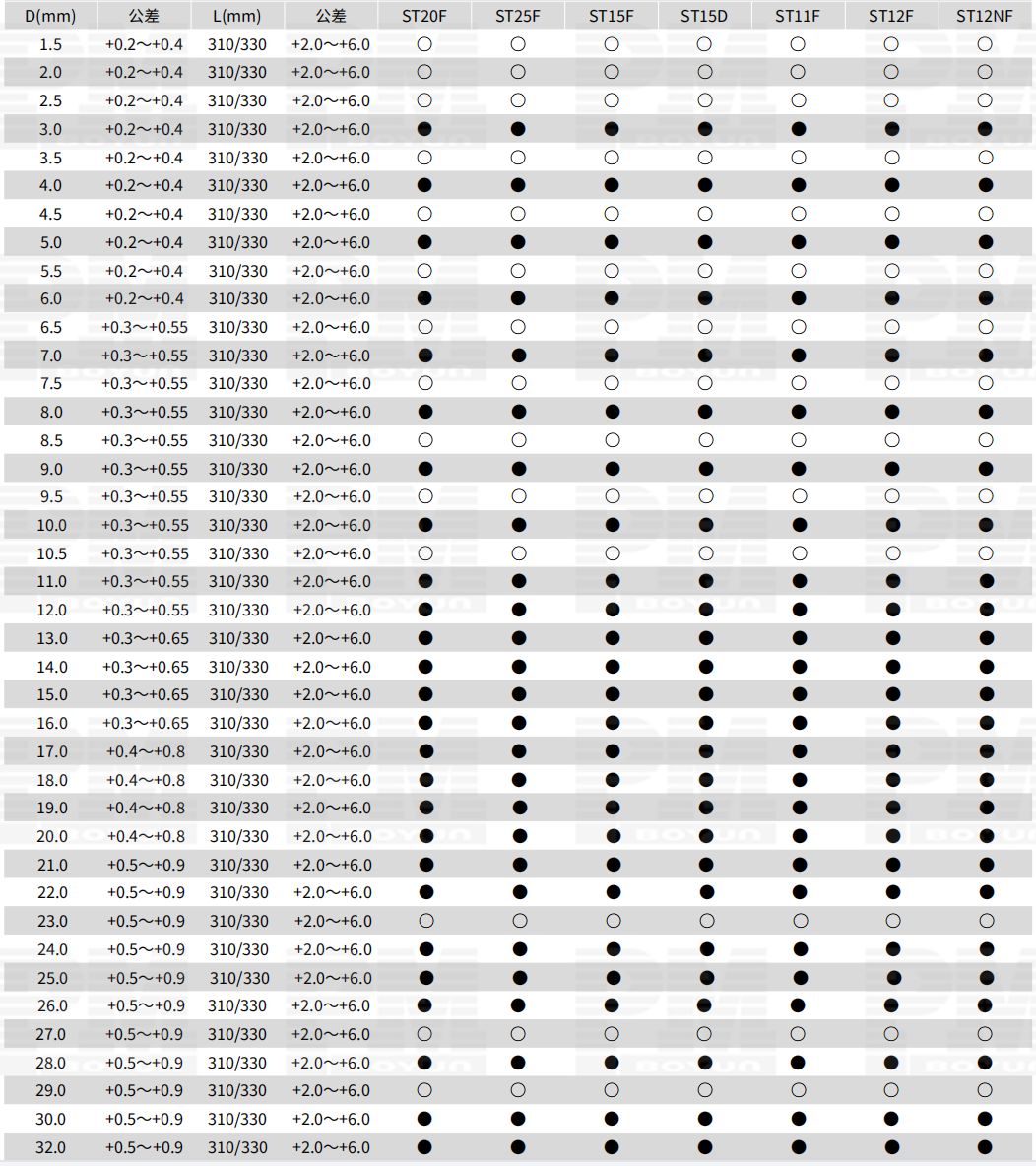

Common Sizes

Grade List

| Giredhi Sumo kune Carbide Rods | |||||||

| Giredhi | Co % | WC saizi yezviyo | HRA | HV | Density (g/cm³) | Kupeta simba (MPa) | Kuputsika kwekuoma (MNm-3/2) |

| KT10F | 6 | Submicron | 92.9 | 1840 | 14.8 | 3800 | 10 |

| KT10UF | 6 | superfine | 93.8 | 2040 | 14.7 | 3200 | 9 |

| KT10NF | 6 | nanometer | 94.5 | 2180 | 14.6 | 4000 | 9 |

| KT10C | 7 | Fine | 90.7 | 1480 | 14.7 | 3800 | 12 |

| KT11F | 8 | Submicron | 92.3 | 1720 | 14.6 | 4100 | 10 |

| KT11UF | 8 | superfine | 93.5 | 1960 | 14.5 | 3000 | 9 |

| KT12F | 9 | superfine | 93.5 | 1960 | 14.4 | 4500 | 10 |

| KT12NF | 9 | nanometer | 94.2 | 2100 | 14.3 | 4800 | 9 |

| KT15D | 9 | Submicron | 91.2 | 1520 | 14.4 | 4000 | 13 |

| KT15F | 10 | Submicron | 92.0 | 1670 | 14.3 | 4000 | 11 |

| KT20F | 10 | Submicron | 91.7 | 1620 | 14.4 | 4300 | 11 |

| KT20D | 10 | Submicron | 92.0 | 1670 | 14.3 | 4500 | 11 |

| KT25F | 12 | superfine | 92.4 | 1740 | 14.1 | 5100 | 10 |

| KT25EF | 12 | superfine | 92.2 | 1700 | 14.1 | 4800 | 10 |

| KT25D | 12 | superfine | 91.5 | 1570 | 14.2 | 4200 | 13 |

| KT37NF | 15 | nanometer | 92.0 | 1670 | 13.8 | 4800 | 10 |

Kuti uwane rumwe ruzivo (MOQ, mutengo, kuendesa) kana kana uchida masevhisi ekugadzirisa, ndapota kumbira mutengo.