Material Performance Table

Customization Service

Tinogona kugamuchira macustomer services.Tinogona kugadzira OEM zvinoenderana nemifananidzo yako uye ODM zvinoenderana nekushandisa kwako zvaunoda.

Iyo inokurumidza kuendesa nguva yezvakagadzirwa zvigadzirwa mazuva manomwe.

Production Process

3.Spray tower drying

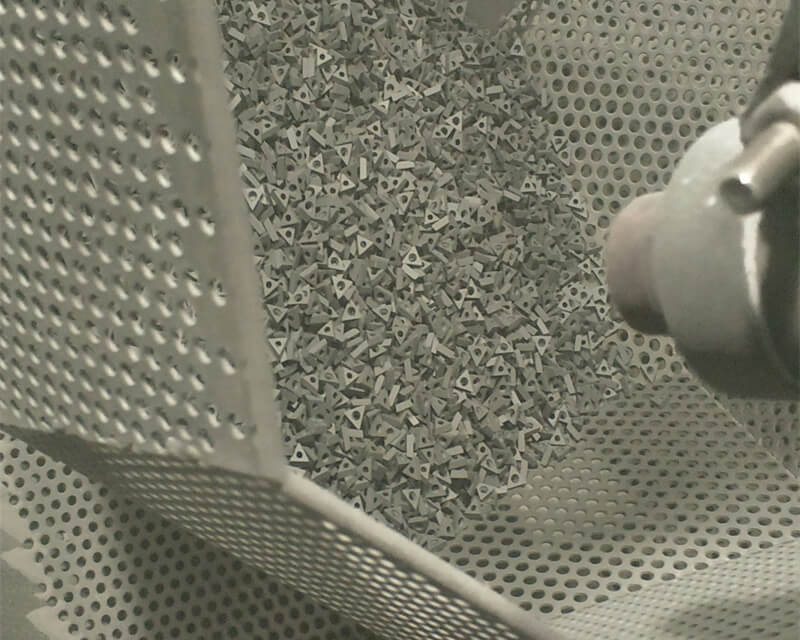

4.Press molding

5.Low pressure sintering furnace sintering

6.Surface kurapwa-Sandblasting

7.Kuongorora

8.Pedzisa kugaya

9.Kuchenesa uye kurongedza

10.Factory re kuongorora

Return Policy

Nezve matambudziko emhando yechigadzirwa akasimbiswa nekambani yedu, tichazoburitsa zvakare zvigadzirwa zvitsva zvinopfuura kuongororwa, uye mari yekufambisa ichatakurwa nekambani yedu.Uye dzorera zvigadzirwa zvisina kukodzera nenguva

Logistics Service

Isu tinoshandira pamwe nemakambani makuru mana epasi rese ekutaura, DHL, FedEx, UPS uye TNT.Kazhinji, nguva yekufambisa nguva iri pakati pe7-10 mazuva.

Isu tinobvumawo migwagwa, ail, ndege uye zvekufambisa mugungwa.

Hunhu Hwakanaka

Nguva yekuvimbisa yehutano yezvigadzirwa zvedu inowanzova gore rimwe chete.Kana paine matambudziko emhando mukati menguva yekuvimbisa, tinogona kudzoka tovatsiva, asi isu hatingatakure dambudziko rekukuvara kwechigadzirwa kunokonzerwa nekushandisa zvisirizvo.

Quality Control

Raw material procurement---Blank production---Chigadzirwa chinopedza Maching---Coating processing

1. Ndiko kuti, WC, Co, Ta, Nb, Ti uye zvimwe zvakasimwa carbide zvigadzirwa zvekugadzira zvinotengwa mufekitori kuti zviongororwe kunaka.

2. Batching, kugaya bhora, granulation, kudzvanya, sintering, blank physical property test, uye kupinda muitiro unotevera mushure mekupasa bvunzo.

3. Iyo isina chinhu inopfuura nepakati pekugadzirisa maitiro senge denderedzwa rekunze, gomba remukati, kuguma kwechiso, shinda, kuumba kugaya uye kumucheto kurapwa, uye inopinda muchirongwa chinotevera mushure mekupfuura kuongorora.

4. Coating hurongwa hwekushandira pamwe mabhizinesi anosanganisira Balchas, aenbond, Suzhou Dingli, nezvimwewo iyo yekupfeka ichave warehouse mushure mekupfuura ongororo.