Cemented carbide imhando yemhando dzakaomarara dzakaumbwa nerefractory simbi yakaoma komboni uye bonding simbi, iyo inogadzirwa nehupfu metallurgy uye ine yakakwirira kupfeka kuramba uye kumwe kuoma. Nekuda kwekuita kwayo kwakanakisa, simende carbide inoshandiswa zvakanyanya mukucheka, kusapfeka-inodzivirira zvikamu, migodhi, geological kuchera, migodhi yemafuta, mekiniki zvikamu uye mimwe minda.

Maitiro ekugadzira ecemented carbide anosanganisira matatu makuru maitiro: musanganiswa kugadzirira, kuumbwa kwekudhinda uye sintering. Saka ndeipi nzira?

Batching muitiro uye musimboti

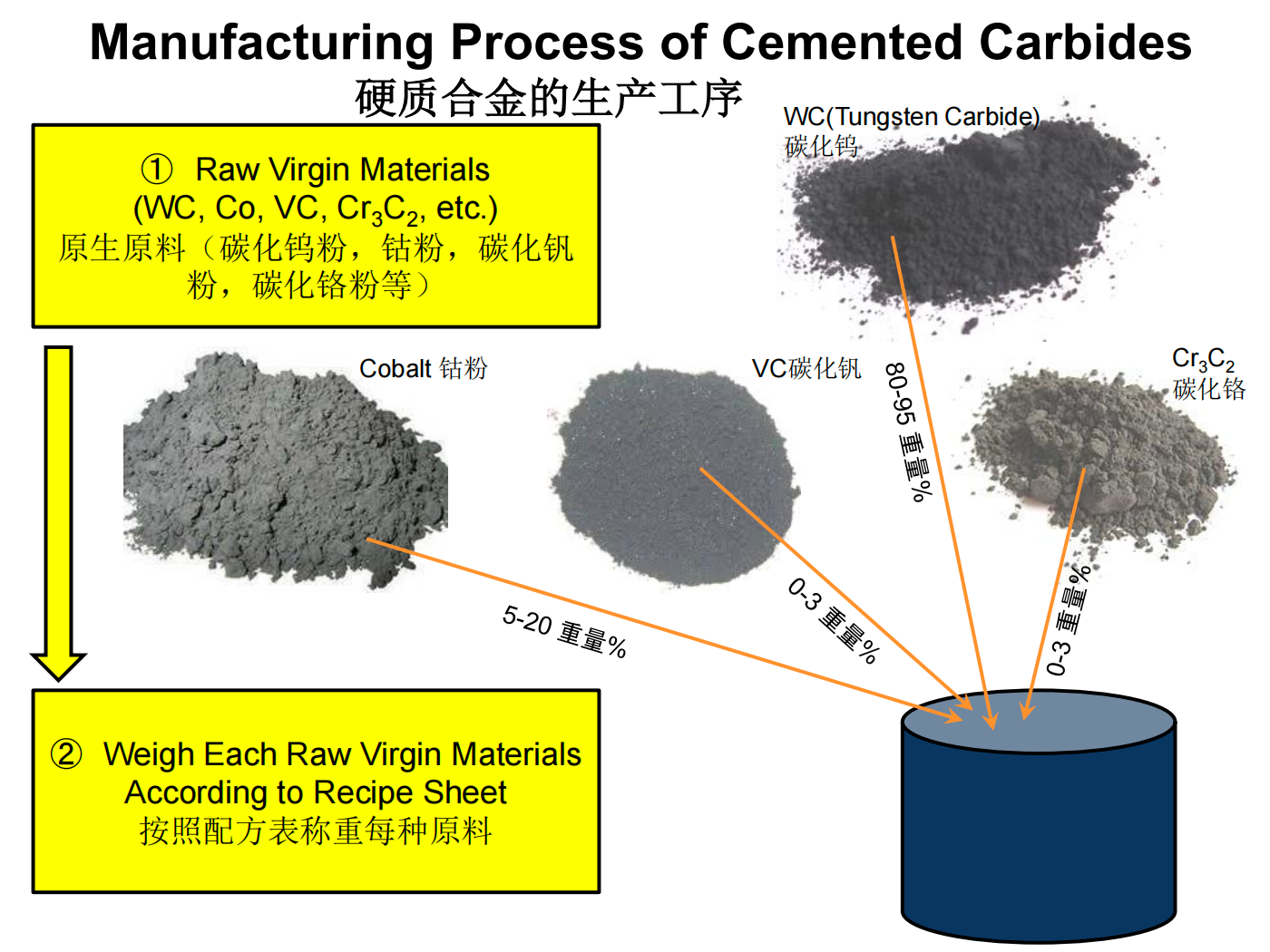

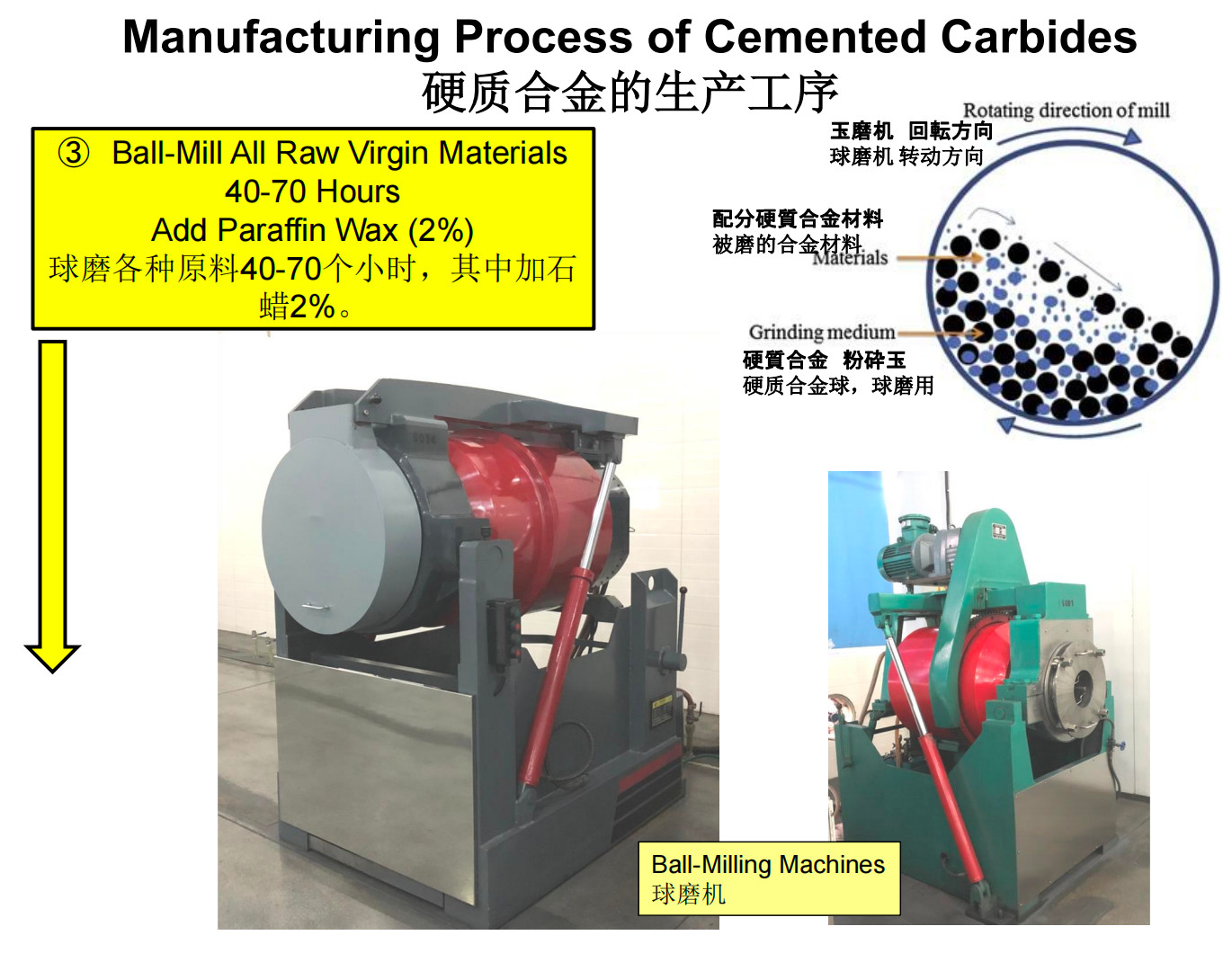

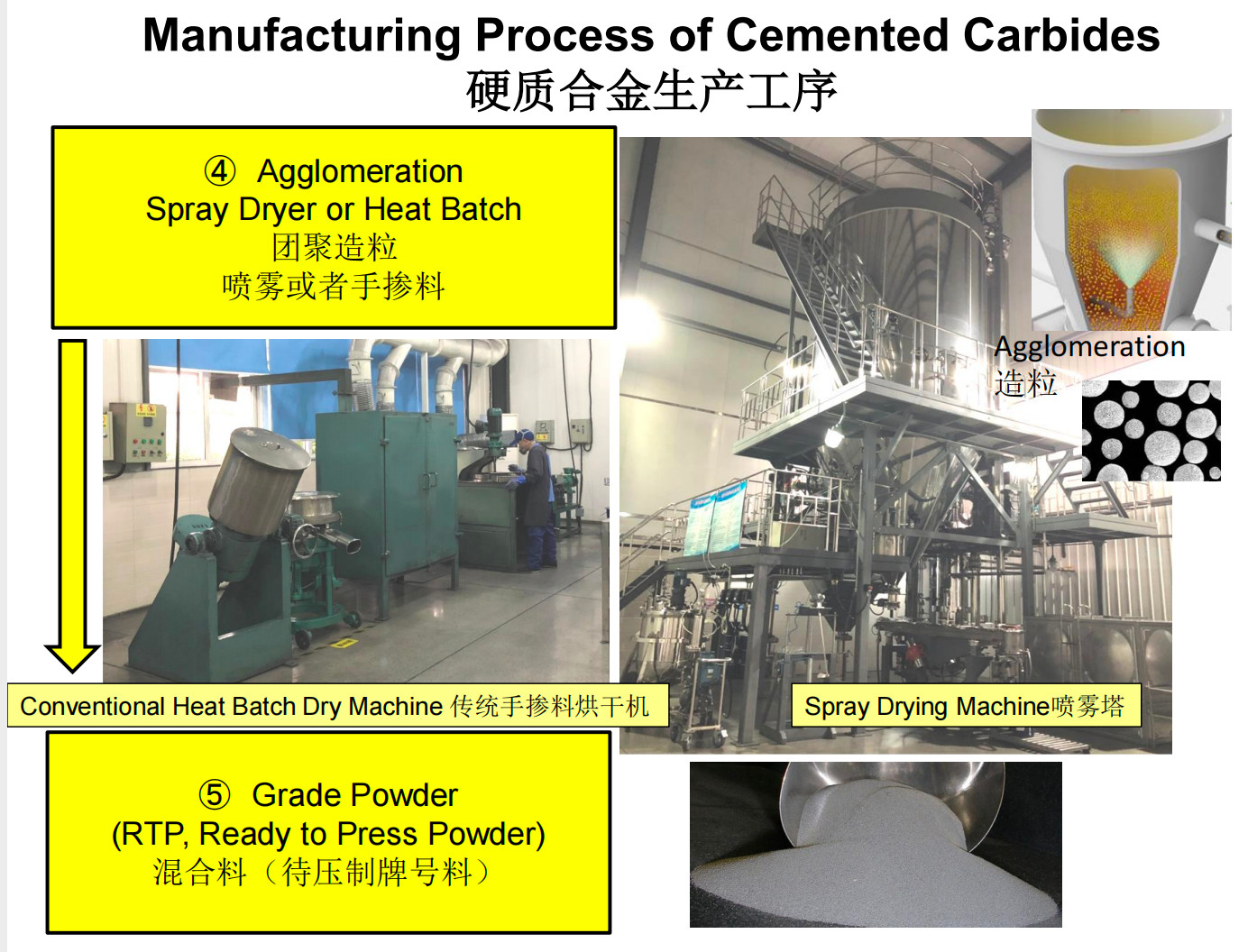

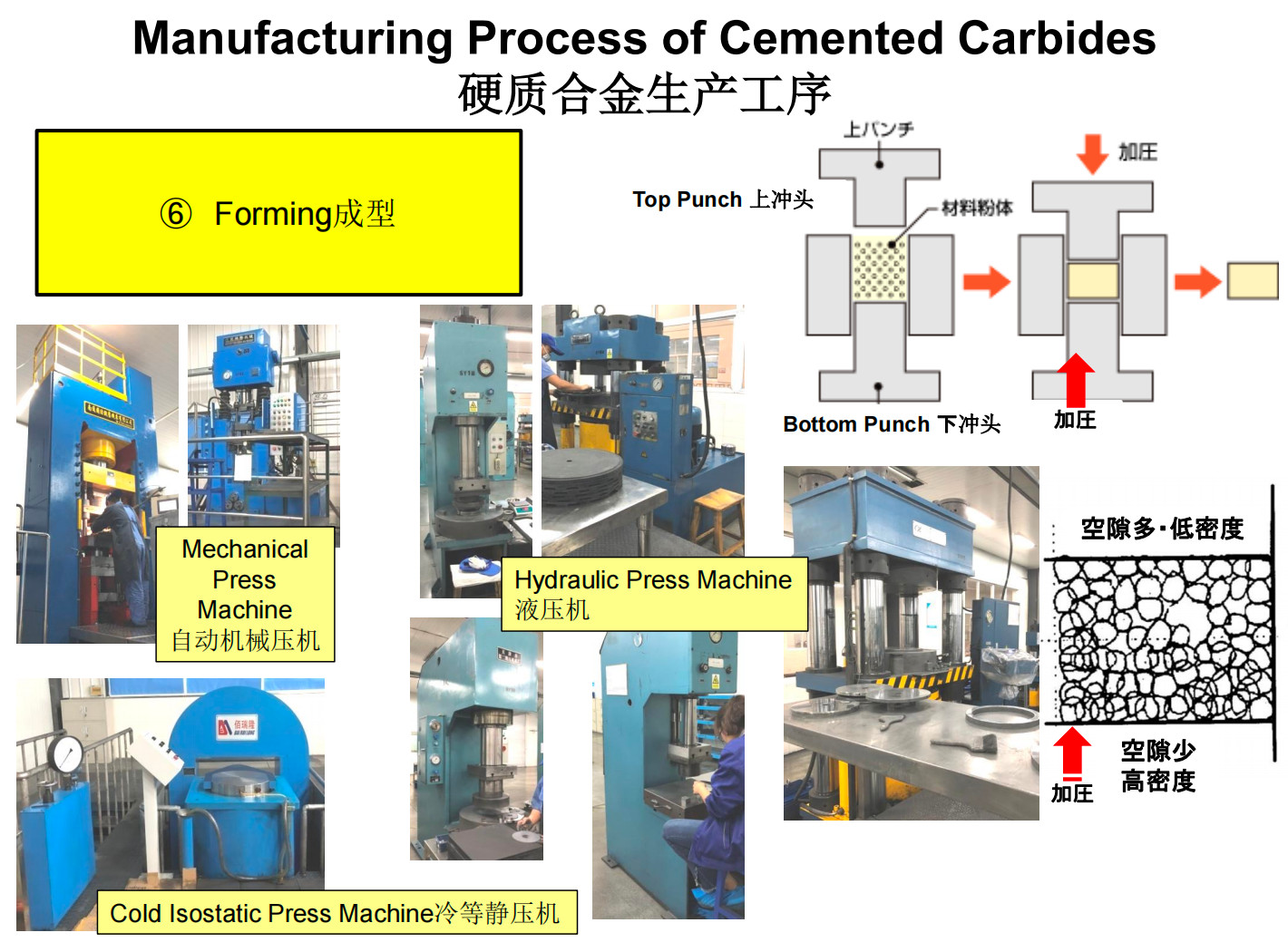

Weresa zvinhu zvinodikanwa (tungsten carbide poda, cobalt poda, vanadium carbide poda, chromium carbide poda uye zvishoma zvekuwedzera), zvisanganise zvinoenderana netafura yeformula, uzviise muchigayo chinotenderedza kana musanganisi kugaya zvakasiyana-siyana mbishi kwemaawa 40-70, wedzera 2% wakisi, paradzira uye gadzira musanganiswa uye gadzira zvigayo zvakaenzana. kumwe kuumbwa uye chidimbu saizi zvinodiwa kuburikidza nekupfapfaidza kuomeswa kana kusanganisa ruoko uye vibrating screening, Kusangana nezvinodiwa zvekutsikirira uye sintering. Mushure mekudzvanya nekunyunguduka, iyo yakasimirirwa carbide blanks inoburitswa uye inoputirwa mushure mekuongororwa kwemhando.

Mixed ingredients

Kukuya nyoro

Glue infiltration, kuomesa uye granulation

Press molding

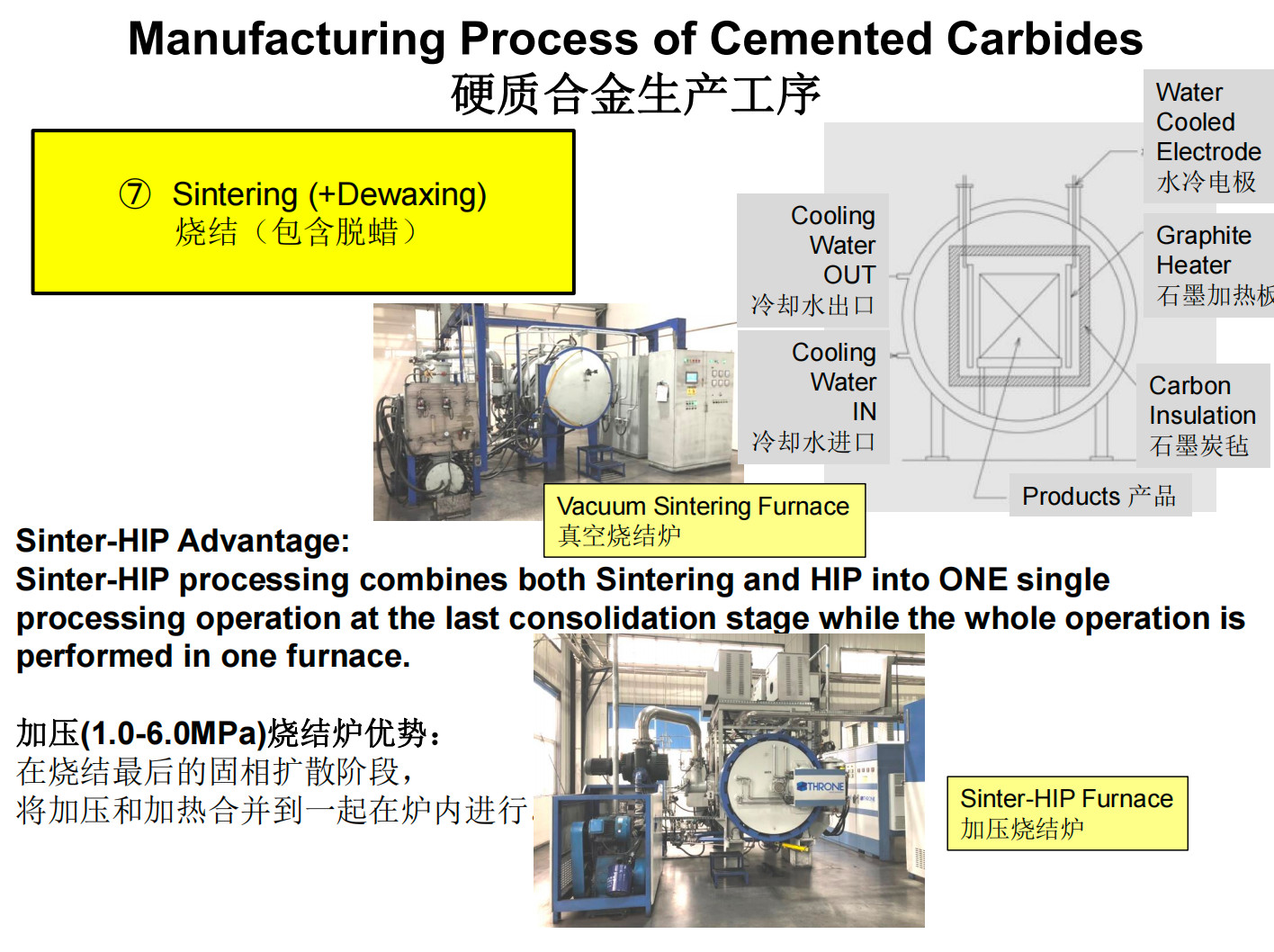

Sinter

Cemented carbide isina chinhu

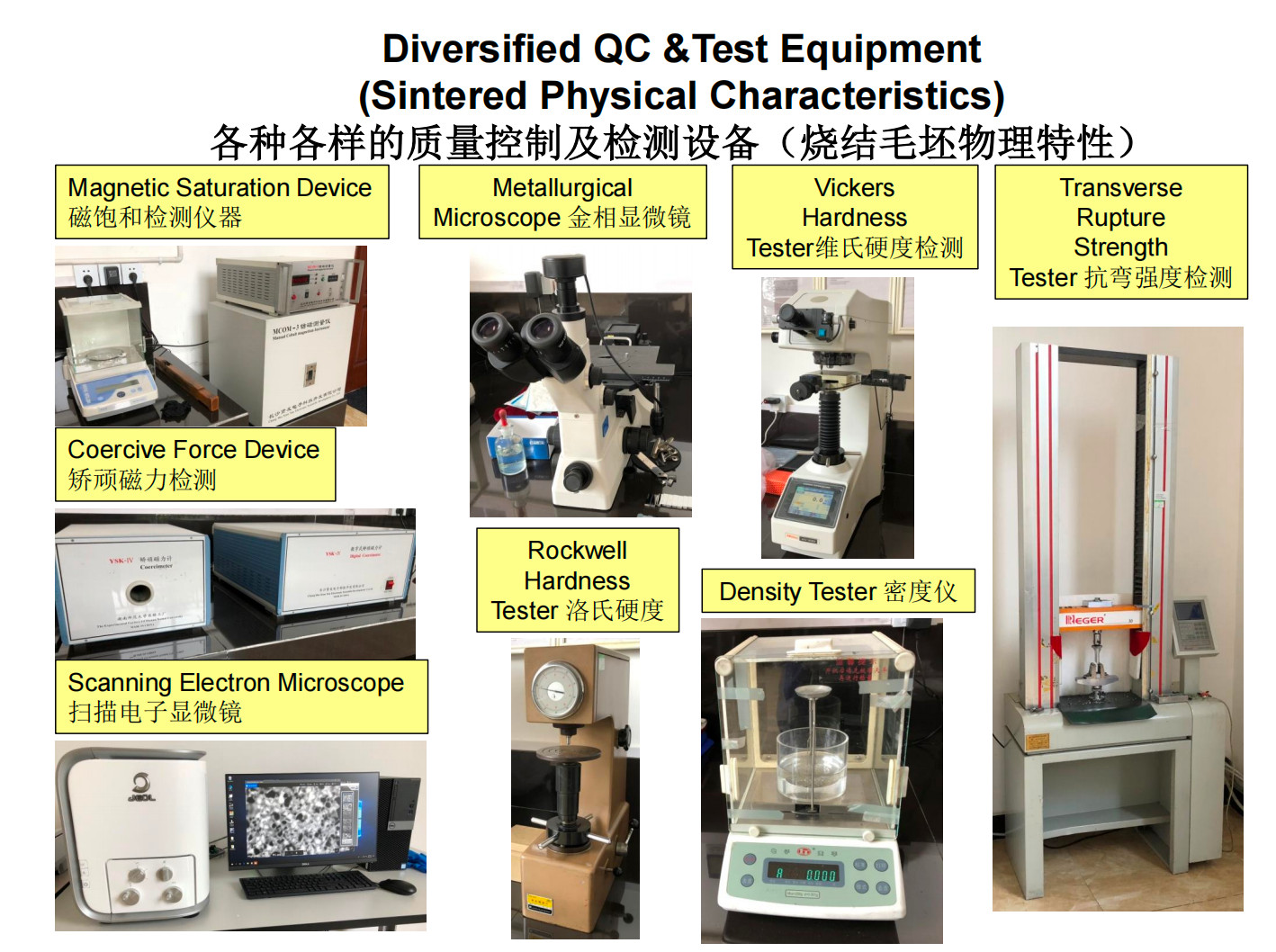

Inspection

Chii chinonzi vacuum?

Vacuum yakaita seiyi inzvimbo ine gasi pressure idiki zvakanyanya pane atmospheric pressure. Mafizikisi anowanzo kurukura nezve yakanakira bvunzo mhinduro mune absolute vacuum, iyo yavanombodaidza vacuum kana yemahara nzvimbo. Zvadaro vacuum isina kukwana inoshandiswa kumiririra vacuum isina kukwana murabhoritari kana muchadenga. Nekune rimwe divi, muinjiniya uye nekushandisa kwemuviri, tinoreva chero nzvimbo yakaderera pane yemhepo.

Yakajairika hurema / tsaona mukugadzirwa kwesimende zvigadzirwa zve carbide

Kutsvaga kumashure kune izvo zvinokonzeresa, anowanzo cemented carbide kugadzirwa kukanganisa / tsaona dzinogona kukamurwa muzvikamu zvina:

Component defects (ETA chikamu chinooneka, mahombe emapoka mapoka anoumba, poda inotsikirira mitswe)

Kukanganisa kugadzirisa (kutsemuka kwewelding, waya yekucheka makatsemuka, kupisa kwemafuta)

Tsaona dzezvakatipoteredza (corrosion, erosion defects, etc.)

Tsaona dzeMechanical (senge brittle kudhumhana, kupfeka, kukuvara kwekuneta, nezvimwewo)

Nguva yekutumira: Jul-27-2022