Ruzivo rwakajairika simbi isina tsvina

Simbi ishoko rinowanzoreva iron-carbon alloys ine kabhoni yemukati pakati pe0.02% ne2.11%. Kupfuura 2.11% isimbi.

Iko kemikari yesimbi inogona kusiyana zvikuru. Simbi ine kabhoni chete inonzi kabhoni simbi kana simbi yakajairika. Mukuita kunyungudutswa kwesimbi, chromium, nickel, manganese, silicon, titanium, molybdenum uye zvimwe zvinhu zvealloy zvinogonawo kuwedzerwa kunatsiridza midziyo yesimbi.

Simbi isina tsvina isimbi ine hunhu hukuru hwekuramba ngura uye kushomeka kwemarara, uye chromium yemukati inokwana 10.5%, uye kabhoni yemukati haipfuure 1.2%.

1. Simbi isingaite ngura?

Kana pane mavara e-brown rust (mavara) pamusoro pesimbi isina tsvina, vanhu vanoshamisika. Vanofunga kuti simbi isina tsvina haigoni kuita ngura. Ngura haisi simbi isina tsvina. Inogona kunge iri nekuda kwedambudziko remhando yesimbi. Kutaura zvazviri, iyi ndiyo maonero asina kunaka kune rumwe rutivi rwekushaya kunzwisisa kwesimbi isina tsvina. Simbi isina tsvina ichaita ngura pasi pemamwe mamiriro ezvinhu. Simbi isina tsvina ine simba rekudzivisa kusvibiswa kwemhepo - rust resistance, uye inokwanisawo kurwisana nekuora mukati mepakati ine asidhi, alkali uye munyu, kureva, kurwisa kwemarara. Nekudaro, kuramba kwayo kwecorrosion kunosiyana nekuumbwa kwayo kwemakemikari, kuwirirana mamiriro, sevhisi mamiriro uye yezvakatipoteredza midhiya mhando. Semuyenzaniso, 304 zvinhu zvine zvakanakisa kusadzivirirwa nekuora mumhepo yakaoma uye yakachena, asi kana ikaendeswa kunharaunda yemahombekombe, ichakurumidza kuita ngura mumhute yegungwa ine munyu wakawanda. Naizvozvo, hapana chero mhando yesimbi isina tsvina inogona kuramba ngura uye ngura chero nguva. Simbi isina tsvina iganda rakatetepa kwazvo, rakasimba uye rakatsetseka rakagadzikana chromium-rich oxide film (inodzivirira firimu) yakaumbwa pamusoro payo kudzivirira maatomu eokisijeni kuti asarambe achipinda uye oxidize, nokudaro kuwana kugona kurwisa ngura. Pane chimwe chikonzero, firimu rinogara richikuvadzwa, maatomu eokisijeni ari mumhepo kana mvura acharamba achipinda kana kuti maatomu esimbi ari musimbi acharamba achiparadzana, achigadzira iron oxide yakasununguka, uye nzvimbo yesimbi inogara iine ngura.

2. Imhando ipi yesimbi isina tsvina isiri nyore kuita ngura?

Pane zvinhu zvitatu zvikuru zvinokanganisa ngura yesimbi isina tsvina.

1) Zvemukati zvealloying zvinhu

Kazhinji kutaura, simbi ine 10.5% chromium yemukati haisi nyore kuita ngura. Iyo yakakwira zvirimo zvechromium uye nickel, zviri nani kupikisa kwekuora. Semuenzaniso, zviri mukati me304 material nickel i8% ~10%, uye zvirimo muchromium i18%~20%. Simbi yakadaro isina tsvina haigoni kuita ngura mumamiriro ezvinhu akajairika.

2) Kunyungudutsa maitiro emabhizinesi ekugadzira

Iyo yekunyungudutsa bhizinesi rekugadzira inozokanganisawo corrosion resistance yesimbi isina tsvina. Miti mikuru yesimbi isina tsvina ine yakanaka yekunyungudutsa tekinoroji, midziyo yepamusoro uye tekinoroji yepamusoro inogona kuvimbiswa maererano nekutonga kwealloying zvinhu, kubviswa kwetsvina, uye kutonga kwebillet kutonhora tembiricha. Nokudaro, hutano hwechigadzirwa hwakagadzikana uye hwakavimbika, hutano hwemukati hwakanaka, uye hazvisi nyore kuita ngura. Pane zvinopesana, zvimwe zvidyarwa zvesimbi zvidiki zvakadzokera kumashure mumidziyo uye tekinoroji. Munguva yekunyunguduka, tsvina haigoni kubviswa, uye zvigadzirwa zvinogadzirwa zvichange zvisingadzivisiki kuita ngura.

3) Mamiriro ekunze

Zvakatipoteredza nemamiriro okunze akaoma uye mhepo yakanaka haisi nyore kuita ngura. Zvisinei, nzvimbo dzine hunyoro hwemhepo, kunoramba kuchinaya, kana kuti acidity yakakwira uye alkalinity mumhepo inongoita ngura. 304 simbi isina tsvina ichaita ngura kana nharaunda yakatenderedza yakashata zvakanyanya.

3. Nzira yekuita sei nemavara ane ngura pasimbi isina tsvina?

1) Nzira dzemakemikari

Shandisa acid yekuchenesa paste kana kupfapfaidza kubatsira zvikamu zvine ngura kuti zvipfuure zvakare kugadzira chromium oxide firimu kudzoreredza kusaita ngura. Mushure mekuchenesa asidi, kuitira kubvisa zvose zvinosvibisa uye masara easidhi, zvakakosha zvikuru kushambidza nemvura yakachena. Mushure mekurapa kwese, porazve nemidziyo yekupolisha uye simbisa newakisi yekupolisha. Kune zvikamu zvine makwapa mashoma, 1: 1 peturu uye musanganiswa wemafuta einjini inogona kushandiswawo kupukuta makwapa e ngura nemamvemve akachena.

2) Mechanical nzira

Kucheneswa kwekuputika, kuputika kwepfuti negirazi kana zvimedu zveceramic, kutsakatisa, kukwesha nekupukuta. Zvinokwanisika kupukuta kusvibiswa kwakakonzerwa nezvinhu zvakambobviswa, zvinhu zvekupukuta kana zvinhu zvakatsakatiswa nemichina. Mhando dzese dzekusvibiswa, kunyanya simbi dzekune dzimwe nyika, dzinogona kukonzeresa ngura, kunyanya munzvimbo ine mwando. Nokudaro, iyo mechanically cleaned surface inofanira kucheneswa zviri pamutemo pasi pemamiriro akaoma. Kushandiswa kwema mechanical nzira kunogona kungochenesa nzvimbo yayo uye haigoni kuchinja kupikisa kwekuora kwezvinhu pachayo. Naizvozvo, zvinokurudzirwa kukwenenzvera zvakare nemidziyo yekupolisha mushure mekuchenesa kwemuchina, uye kusimbisa newakisi yekupolisha.

4. Simbi isina simbi inogona kutongwa nemagineti here?

Vanhu vazhinji vanoenda kunotenga simbi isina tsvina kana zvigadzirwa zvesimbi uye vanounza diki magineti nazvo. Pavanotarisa zvinhu, vanofunga kuti simbi yakanaka yesimbi ndiyo isingabatiki. Pasina magnetism, hapazovi nengura. Kutaura zvazviri, uku kunzwisisa kusina kururama.

Iyo isiri-magnetic Stainless simbi bhendi inotarirwa nechimiro. Munguva yekusimba kwesimbi yakanyungudutswa, nekuda kwekusiyana kwekuomesa tembiricha, inoumba simbi isina tsvina ine chimiro chakasiyana senge "ferrite", "austenite" uye "martensite", pakati payo "ferrite" uye "martensite" simbi isina tsvina ine magineti. "Austenitic" Stainless simbi ine yakanaka comprehensive mechanical properties uye weldability, asi "ferritic" Stainless simbi ine magineti yakasimba kudarika "austenitic" Stainless simbi chete maererano nekudzivisa ngura.

Parizvino, iyo inonzi 200 series uye 300 series stainless steels ine high manganese content uye yakaderera nickel yemukati mumusika zvakare haina magnetism, asi kuita kwavo kuri kure neiyo ye304 ine yakakwira nickel. Pane zvinopesana, 304 ichave zvakare ine micro-magnetism mushure mekutambanudza, annealing, polishing, casting uye mamwe maitiro. Nokudaro, kusanzwisisana uye kusava nesayenzi kutonga zvakanakira nekuipira kwesimbi isina tsvina nekushandisa simbi isina magineti.

5. Ndeapi mhando dzesimbi dzinowanzoshandiswa?

201: Manganese inoshandiswa pachinzvimbo chenickel simbi isina tsvina, ine imwe asidhi uye alkali kuramba, kukwirira kwepamusoro, kupukuta uye kusina mabhubhu. Inoshandiswa kumakesi ekuona, machubhu ekushongedza, machubhu eindasitiri uye zvimwe zvigadzirwa zvisina kudzika zvakadhonzwa.

202: Ndeyakaderera nickel uye yakakwira manganese simbi isina tsvina, ine nickel uye manganese zvirimo zvingangoita 8%. Pasi pemamiriro asina simba ekuora, inogona kutsiva 304, ine mutengo wakakwira kuita. Inonyanya kushandiswa mukushongedza kwekuvaka, highway guardrail, mainjiniya emagetsi, girazi handrail, migwagwa mikuru, nezvimwe.

304: General Stainless Simbi, ine yakanaka corrosion resistance, heat resistance, low tembiricha simba uye michina zvinhu, uye kuomarara kwakanyanya, inoshandiswa muindasitiri yechikafu, indasitiri yezvokurapa, indasitiri, indasitiri yemakemikari, uye indasitiri yekushongedza imba.

304L: yakaderera kabhoni 304 simbi isina tsvina, inoshandiswa kune midziyo yemidziyo ine corrosion resistance uye formability.

316: Nekuwedzera kweMo, ine yakanakisa tembiricha yekupisa corrosion uye inoshandiswa muminda yemidziyo yemvura yegungwa, chemistry, indasitiri yechikafu uye kugadzira mapepa.

321: Iyo ine yakanakisa tembiricha yekusimbisa kutyora kuita uye yakanyanya tembiricha inokambaira kuramba.

430: Kupisa kusingaite kuneta, kupisa kwekuwedzera coefficient idiki pane iyo yeaustenite, uye inoshandiswa kune midziyo yemumba nekushongedza kwekuvaka.

410: Iine kuoma kwepamusoro, kuoma, kumira zvakanaka kwecorrosion, hombe yekupisa yekupisa, diki yekuwedzera coefficient, uye yakanaka oxidation kuramba. Inoshandiswa kugadzira mhepo, mhute yemvura, mvura uye oxidizing acid inoparadza zvikamu.

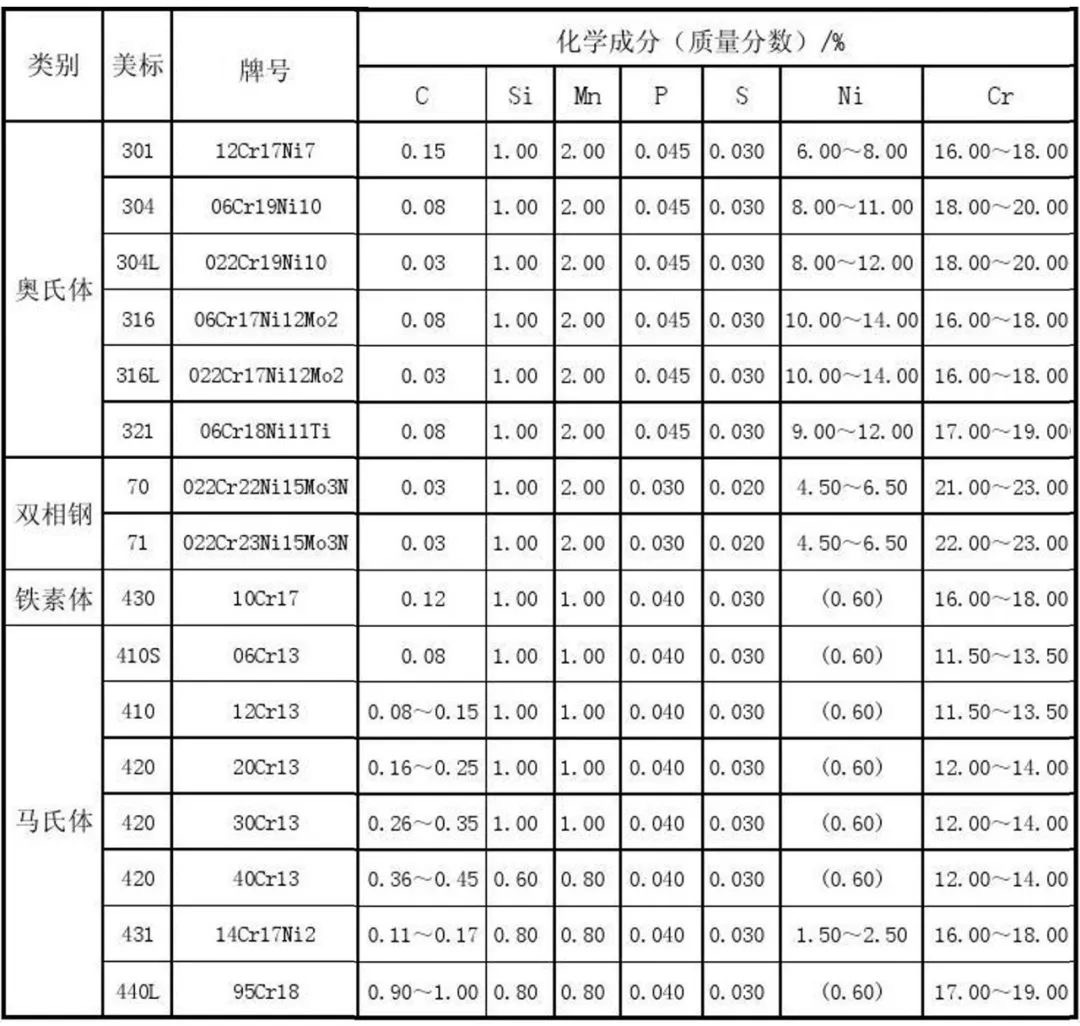

Inotevera tafura yemukati ye "alloy element" yeakasiyana simbi mamakisi eyakajairwa Stainless simbi yekutarisa chete:

Nguva yekutumira: Jan-30-2023