Products

Yepamusoro Precision Tungsten Carbide Yakakwenenzverwa Tsvimbo Round Bar

Product Sumo

Carbide tsvimbo dzinonyanya kushandiswa kuchera mabheti, ekupedzisira-milling cutters uye mawinji. Inogona zvakare kushandiswa kucheka, kutsika uye kuyera maturusi. Inoshandiswa mumapepa, kurongedza, kudhinda, isiri-ferrous metal processing industry. Pamusoro pezvo, inoshandiswa zvakanyanya mukugadzira macheki esimbi anomhanya kwazvo, kucheka kwecarbide milling cutter, NAS yekucheka maturusi, aviation cutters, simende carbide bits, milling cutter core bits, high speed simbi, taperd milling cutters, metric milling cutters, micro end milling cutters, hinge pilot, electronic tool,carbide rotary faira, simende carbide chishandiso, nezvimwe.

Product Details

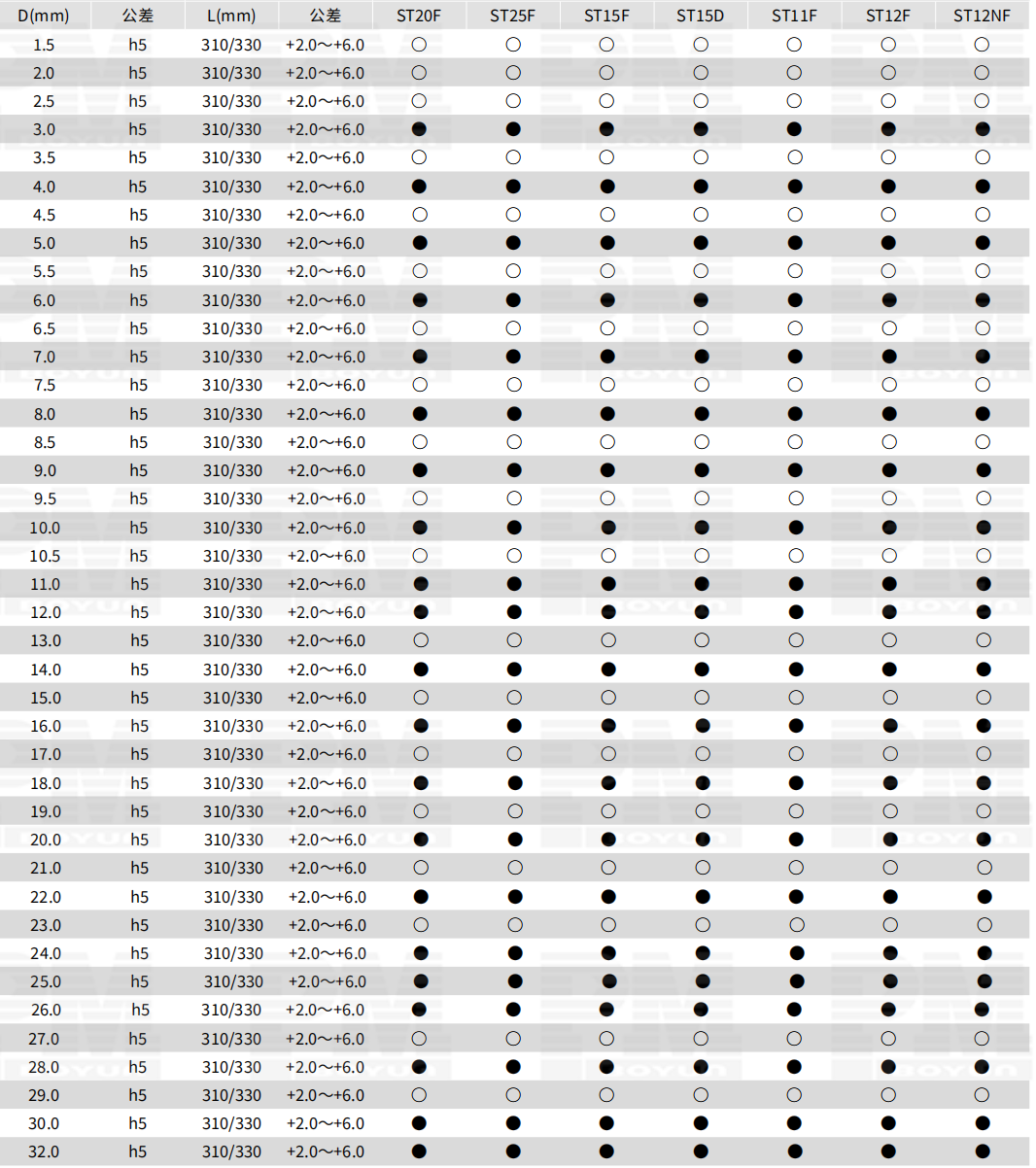

Referenced Sizes

Material Giredhi Chati

| Giredhi Sumo kune Carbide Rods | |||||||

| Giredhi | Co % | WC saizi yezviyo | HRA | HV | Density (g/cm³) | Kupeta simba (MPa) | Kuputsika kwekuoma (MNm-3/2) |

| KT10F | 6 | Submicron | 92.9 | 1840 | 14.8 | 3800 | 10 |

| KT10UF | 6 | superfine | 93.8 | 2040 | 14.7 | 3200 | 9 |

| KT10NF | 6 | nanometer | 94.5 | 2180 | 14.6 | 4000 | 9 |

| KT10C | 7 | Fine | 90.7 | 1480 | 14.7 | 3800 | 12 |

| KT11F | 8 | Submicron | 92.3 | 1720 | 14.6 | 4100 | 10 |

| KT11UF | 8 | superfine | 93.5 | 1960 | 14.5 | 3000 | 9 |

| KT12F | 9 | superfine | 93.5 | 1960 | 14.4 | 4500 | 10 |

| KT12NF | 9 | nanometer | 94.2 | 2100 | 14.3 | 4800 | 9 |

| KT15D | 9 | Submicron | 91.2 | 1520 | 14.4 | 4000 | 13 |

| KT15F | 10 | Submicron | 92.0 | 1670 | 14.3 | 4000 | 11 |

| KT20F | 10 | Submicron | 91.7 | 1620 | 14.4 | 4300 | 11 |

| KT20D | 10 | Submicron | 92.0 | 1670 | 14.3 | 4500 | 11 |

| KT25F | 12 | superfine | 92.4 | 1740 | 14.1 | 5100 | 10 |

| KT25EF | 12 | superfine | 92.2 | 1700 | 14.1 | 4800 | 10 |

| KT25D | 12 | superfine | 91.5 | 1570 | 14.2 | 4200 | 13 |

| KT37NF | 15 | nanometer | 92.0 | 1670 | 13.8 | 4800 | 10 |

Nyora meseji yako pano ugotitumira