Products

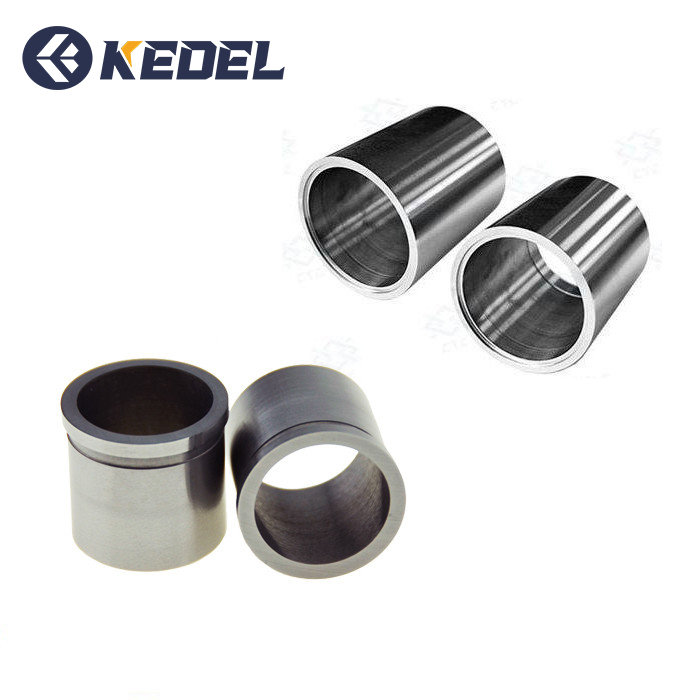

Cemented Tungsten Carbide Sleeves Bushings For Submersibe Oil Field

Product Sumo

Tungsten carbide sleeve application yakakura, inova chishandiso chekudzivirira kirasi yezvikamu. Iri mubasa chairo uye basa uye chinangwa chenzvimbo yekushandiswa kwayo zvine hukama hukuru.

Mavharuvhu maapplication, bushings aiswe muvhavha stem cap trap, kuitira kudzikisa kudonha kwevharuvhu, kuvhara; kutakura zvikumbiro, kushandiswa kwegwenzi kuderedza kupera pakati pekutakura uye chigaro cheshaft, dzivisa mukaha pakati pegomba uye gomba rinowedzera zvichingodaro.

Tungsten carbide sleeve kugadzirwa uye kugadzirisa kwehurefu-simba, inogona kumira kwenguva refu, ine yakakwira makemikari kugadzikana, alkali, doro, ether, hydrocarbons, asidhi, mafuta, detergent, mvura (mvura yegungwa), uye haina kunhuwa, isiri-chepfu, isinganakidze, isiri-ngura maitiro, ayo anoshandiswa zvakanyanya muindasitiri yepetrochemical ye Submerged Oil Pombi, Pumpluc Pump, mvura yepombi.

zvakanakira

1, 100% Raw zvinhu:

Bushings inogadzirwa nezvinhu zvakachena, izvo zvine maitiro ehupenyu hurefu hwebasa uye kushanda kwakagadzikana.

2, Maching:

Bushings inogadziriswa nepamusoro-chaiyo michina: CNC machining Center, muchina wekukuya, muchina wekugaya, muchina wekuchera, wakachinjika muchina wekugaya, chamfering muchina, Metal Stamping, CNC yekucheka muchina nezvimwe.

3, akawanda saizi aripo:

Tinogona kupa kutakura bushings hukuru hwakasiyana, molds yakakwana uye nguva pfupi yekuendesa.7-10 mazuva emasampuli .20-25 mazuva ekushanda kwekugadzirwa kwemazhinji

4,Simbiso yehutano:

Unsurpassed Quality Standards.Our bushings sleeve mabearings akagadzirwa uye anogadzirwa zvinoenderana neyakaomesesa yemhando zviyero zvinotonga kusarudzwa kwezvinhu, machining, kupera kwepamusoro, kuongorora uye kurongedza.

Exhibit

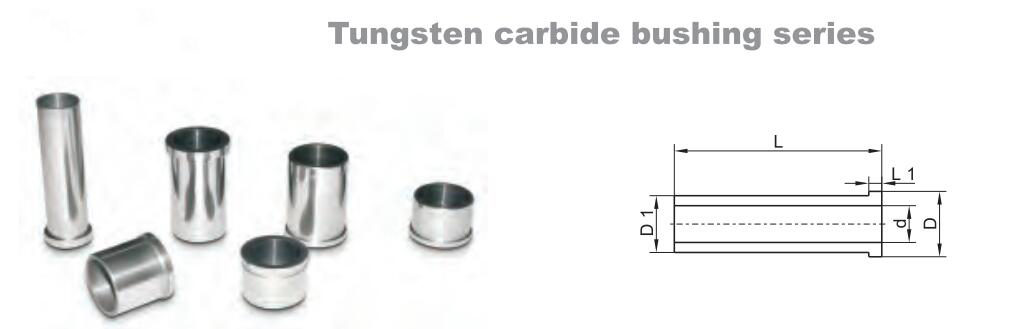

Detail drawing

Tafura yezvinhu

| Giredhi | ISO | Tsanangudzo | Kushandiswa kwe tungsten carbide | ||

| Density | TRS | Kuoma | |||

| G/Cm3 | N/mm2 | HRA | |||

| YG06X | K10 | 14.8-15.1 | ≥1560 | ≥91.0 | Inokodzera machining echilled cast iron, alloy cast iron, refractory simbi uye alloy simbi. Uyewo Akakodzera kugadzirwa kwesimbi yakajairwa. |

| YG06 | K20 | 14.7-15. 1 | ≥1670 | ≥89.5 | Inokodzera kupedzisa machining uye semi-yekupedzisira machining yesimbi yakakandwa, isiri-ferrous simbi, alloy uye isina alloyed zvinhu. Inokodzerawo kudhirowa kwewaya yesimbi uye isiri-ferrous simbi, electric drill yekushandisa geology uye simbi yekudhirowa nezvimwe. |

| YG08 | K20-K30 | 14.6-14.9 | ≥1840 | ≥89 | Anokwanisa kuita rough machining of cast iron, non-ferrous metal, non-metal materials, kudhirowa kwesimbi, non-ferrous simbi nemapombi, zviboorero zvakasiyana-siyana zvekushandisa geology, maturusi ekugadzira muchina nekupfeka zvikamu. |

| YG09 | K30-M30 | 14.5-14.8 | ≥2300 | ≥91.5 | Inokodzera yakaderera kumhanya rough machining, milling titanium alloy uye refractory alloy, kunyanya yekucheka-kubvisa chishandiso uye sirika prick. |

| YG11C | K40 | 14-.3-14.6 | ≥2100 | ≥86.5 | Inokodzera kuumba madhiri eheavy-duty rock drill: mabheti anobvisika anoshandiswa kuchera gomba rakadzika, rock drill trolley nezvimwe. |

| YG15 | K40 | 13.9-14.1 | ≥2020 | ≥86.5 | Inokodzera kuchera dombo rakaomarara, simbi dzesimbi dzine yakakwira compression ratios, pombi kudhirowa, punching maturusi, core cabinet yepowder metallurgy automatic molders etc. |

| YG20 | 13.4-14.8 | ≥2480 | ≥83.5 | Inokodzera kugadzira inofa ine yakaderera maitiro sekubaya mawachi zvikamu, mabhomba ebhatiri, madiki screw caps nezvimwe. | |

| YG25 | 13.4-14.8 | ≥2480 | ≥82.5 | Inokodzera kugadzira mold yemusoro unotonhora, kutonhora kutsika uye kutonhora kudzvanya kunoshandiswa kugadzira zvikamu zvakajairwa, mabheji nezvimwe. | |

Dimension table

| Muenzaniso Nha. | Tsanangudzo | OD(D:mm) | ID(D1:mm) | Pore(d:mm) | Kureba(L:mm) | Kureba kwenhanho(L1:mm) |

| KD-2001 | 01 | 16.41 | 14.05 | 12.70 | 25.40 | 1.00 |

| KD-2002 | 02 | 16.41 | 14.05 | 12.70 | 31.75 | 1.00 |

| KD-2003 | 03 | 22.04 | 18.86 | 15.75 | 31.75 | 3.18 |

| KD-2004 | 04 | 22.04 | 18.86 | 15.75 | 50.80 | 3.18 |

| KD-2005 | 05 | 16.00 | 13.90 | 10.31 | 76.20 | 3.18 |

| KD-2006 | 06 | 22.00 | 18.88 | 14.30 | 25.40 | 3.18 |

| KD-2007 | 07 | 24.00 | 21.00 | 16.00 | 75.00 | 3.00 |

| KD-2008 | 08 | 22.90 | 21.00 | 15.00 | 75.00 | 3.00 |

| KD-2009 | 09 | 19.50 | 16.90 | 12.70 | 50.00 | 4.00 |

| KD-2010 | 10 | 36.80 | 32.80 | 26.00 | 55.00 | 4.00 |