Products

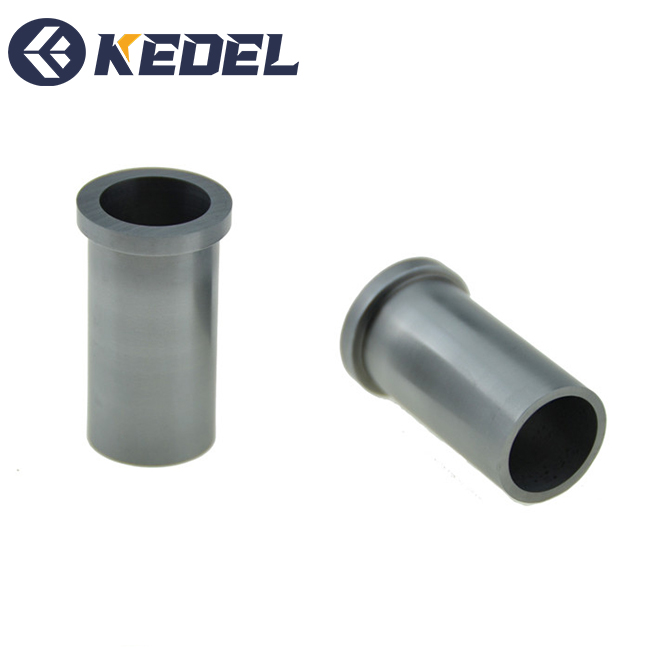

Anti Corrosion Tungsten Carbide Solid YG1C Threaded Drill Bushings

Product Sumo

Tungsten carbide bushing yakaiswa nemhandara tungsten carbide zvinhu. Inoratidza kuoma kwepamusoro uye simba rekukotama. Izvo zvine basa repamusoro pakuramba abrasion uye corrosion, iyo inoshandiswa zvakanyanya mumaindasitiri mazhinji.

Kuti ishandiswe zvakanyanya. Tungsten carbide bushing inowanzogadzirwa nehupamhi hwepamusoro, uye nekuda kwekupedza kwavo kwakaringana, chaiyo dimension, kusimba uye kushora kuramba. Izvi zvinofarirwa zvakanyanya nevatengi pamusika we dostic uye mukati.

Mukuwedzera, siyana kubva kwakasiyana-siyana kwenzvimbo yekushandisa. Kune akati wandei marudzi eTungsten carbide bushing. Zvizhinji zvezvinotsanangurwa zvese zvakagadziridzwa. Kedel Tool yakatsigirwa nehupfumi indasitiri ruzivo uye ruzivo rwekugadzira akasiyana Tungsten carbide bushing. Izvi zvinogona kuburitsa akasiyana eTungsten carbide bushing zvichibva pane chaiyo dhizaini.

Product Features

1. Shandisa 100% tungsten carbide mbishi zvinhu

2. Yakagadzikana makemikari zvinhu

3. Kuita kwakanakisa uye kupfeka kwakanaka / corrosion kuramba

4. HIP sintering, yakanaka compactness

5. Mabhangi, yakakwirira machining kururama / nemazvo

6. OEM customized saizi iripo

7. Kupihwa kwefekitari

8. Zvigadzirwa zvakasimba kuongororwa kwehutano

Detail drawing

Tafura yezvinhu

| Giredhi | ISO | Tsanangudzo | Kushandiswa kwe tungsten carbide | ||

| Density | TRS | Kuoma | |||

| G/Cm3 | N/mm2 | HRA | |||

| YG06X | K10 | 14.8-15.1 | ≥1560 | ≥91.0 | Inokodzera machining echilled cast iron, alloy cast iron, refractory simbi uye alloy simbi. Uyewo Akakodzera kugadzirwa kwesimbi yakajairwa. |

| YG06 | K20 | 14.7-15. 1 | ≥1670 | ≥89.5 | Inokodzera kupedzisa machining uye semi-yekupedzisira machining yesimbi yakakandwa, isiri-ferrous simbi, alloy uye isina alloyed zvinhu. Inokodzerawo kudhirowa kwewaya yesimbi uye isiri-ferrous simbi, electric drill yekushandisa geology uye simbi yekudhirowa nezvimwe. |

| YG08 | K20-K30 | 14.6-14.9 | ≥1840 | ≥89 | Anokwanisa kuita rough machining of cast iron, non-ferrous metal, non-metal materials, kudhirowa kwesimbi, non-ferrous simbi nemapombi, zviboorero zvakasiyana-siyana zvekushandisa geology, maturusi ekugadzira muchina nekupfeka zvikamu. |

| YG09 | K30-M30 | 14.5-14.8 | ≥2300 | ≥91.5 | Inokodzera yakaderera kumhanya rough machining, milling titanium alloy uye refractory alloy, kunyanya yekucheka-kubvisa chishandiso uye sirika prick. |

| YG11C | K40 | 14-.3-14.6 | ≥2100 | ≥86.5 | Inokodzera kuumba madhiri eheavy-duty rock drill: mabheti anobvisika anoshandiswa kuchera gomba rakadzika, rock drill trolley nezvimwe. |

| YG15 | K40 | 13.9-14.1 | ≥2020 | ≥86.5 | Inokodzera kuchera dombo rakaomarara, simbi dzesimbi dzine yakakwira compression ratios, pombi kudhirowa, punching maturusi, core cabinet yepowder metallurgy automatic molders etc. |

| YG20 | 13.4-14.8 | ≥2480 | ≥83.5 | Inokodzera kugadzira inofa ine yakaderera maitiro sekubaya mawachi zvikamu, mabhomba ebhatiri, madiki screw caps nezvimwe. | |

| YG25 | 13.4-14.8 | ≥2480 | ≥82.5 | Inokodzera kugadzira mold yemusoro unotonhora, kutonhora kutsika uye kutonhora kudzvanya kunoshandiswa kugadzira zvikamu zvakajairwa, mabheji nezvimwe. | |